When managing a construction site, effective waste management is key. Best practices include planning ahead to minimize waste, sorting debris on-site into recyclable streams, safely handling hazardous materials, and training your crew. These steps can cut disposal costs and environmental impact. For example, U.S. EPA data shows over 500 million tons of construction and demolition debris are generated each year. To keep that waste under control, start with a solid plan (accurate ordering and “just-in-time” deliveries), and use sturdy containers and clear sorting stations from day one. Below are expert tips to make your next project cleaner, safer, and more efficient.

1. Plan Ahead and Reduce Waste

Begin waste planning before dirt ever moves. Estimate material needs carefully so you don’t overbuy. Schedule deliveries “just in time” (smaller, frequent drops) to prevent damage from sitting on site. Whenever possible, use prefabricated components (pre-cut lumber, wall panels, plumbing pods, etc.) – these are made in factories to exact specs, greatly reducing off-cuts and scrap on site. Develop a simple waste plan: set clear reduction goals (for example, 50–75% waste diversion) and assign who on your crew handles sorting and disposal.

- Accurate Estimation: Order only what you need. Less excess means less to throw away.

- Just-In-Time Deliveries: Stagger material shipments so they arrive as needed. This avoids spoilage and frees up space.

- Prefab & Modular Use: Incorporate pre-built walls or modules when you can. Factory-built pieces fit perfectly, so you cut boards and metal much less.

- Crew Training: Educate everyone (including subcontractors) from day one. A quick toolbox talk on waste sorting and handling lets your team know the plan.

Each of these steps helps shrink your waste before it even appears. EPA guidelines also recommend planning frequent waste pickups to keep bins from overflowing. When waste services are scheduled ahead, trash doesn’t pile up, keeping the site clean and compliant.

2. Segregate, Recycle, and Reuse

Once construction begins, sort waste at the source. Set up clearly labeled bins or dumpsters for major materials: wood, metal, concrete/cement, drywall, cardboard, etc. Color-coded containers and big, simple signs can guide crews (and reduce contamination of recyclables). For example, one bin might be painted green for clean wood, another blue for metal. Place these containers close to work areas so it’s easy to toss scraps in the right spot.

- Separate Bins: Keep wood, metals, concrete, plastics, and general debris apart. This maximizes recycling opportunities. (The EPA advises locating these bins away from stormwater flow and keeping them covered in rain.)

- Organized Waste Yard: Designate a flat, level area for dumpsters. Put them on high ground, not where rainwater pools, and put lids or tarps on them so rain and wind can’t scatter trash.

- Partner with Recyclers: Work with your hauler or a local materials recovery facility (MRF). Some companies will accept mixed loads and sort them off-site, while others pick up separated streams. Either way, recycling lots of material lowers disposal fees and can even earn rebates (for example, scrap metal has value).

- Salvage & Reuse: Anything reusable should be pulled out of the waste stream. For instance, scrap lumber or brick left over can be used on-site or in another project. The EPA notes that “wood salvaged during deconstruction can be used for other projects”. Old fixtures (doors, windows, cabinets) can be stored for future use or donated to building-material reuse centers. Reusing or donating these items saves you from buying new and keeps perfectly good materials out of a landfill.

- Concrete Recycling: Concrete and masonry are heavy but often clean waste. If you have the space, consider hiring a portable concrete crusher. You can crush rubble into gravel right on site and use it as fill under driveways or as base material, which slashes dump fees.

By segregating, you make it far easier to recycle. A clean bin of scrap metal goes straight to the recycler, while mixed debris is usually landfill-bound. Proper sorting therefore maximizes diversion.

3. Use the Right Containers On-Site

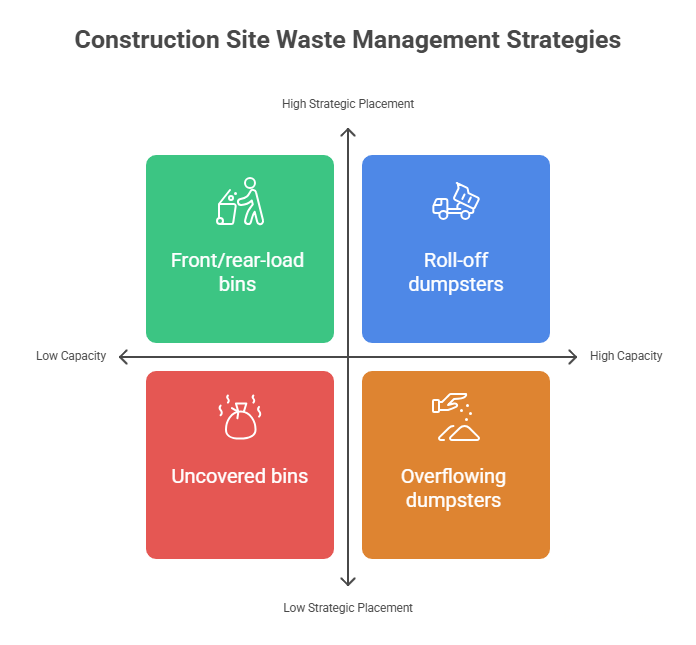

Choose durable roll-off dumpsters and bins. Heavy-duty containers built for construction (like the roll-off dumpster shown above) will withstand rugged use. Rent or own containers with the right capacity: large roll-offs for bulky debris, smaller front- or rear-load bins for leftover drywall or general trash. Position them strategically around the site so workers aren’t hauling waste too far.

Make sure bins have covers or lids. Water running through open debris piles can carry pollutants into storm drains, so cover dumpsters with tarp or lids whenever it rains. Keep lids closed between uses to prevent wind from blowing out trash or rain from soaking cardboard. Also, schedule regular pickups – don’t let a dumpster overflow. The EPA advises scheduling waste collection often enough so bins never get too full. Overflowing containers are not only messy, they can become safety hazards.

On a busy site, consider a mix of bin types. Roll-off dumpsters (like those offered by Refuse Fab) handle large volumes and are easy for trucks to haul away. For narrow or indoor spaces, front/rear-load bins let crews dump smaller loads into a separate truck. Label each container (even with spray paint or tape) to show what goes in it. For example: “Metal Only,” “Wood Only,” or “Mixed Debris.”

4. Handle Hazardous Materials Safely

Not all waste can be tossed together. Materials like paints, solvents, adhesives, batteries, oils, and chemicals are hazardous and need special care. Treat them separately:

- Keep it Contained: Store hazardous liquids and materials in their original containers or in approved, clearly labeled drums. Place these bins well away from general trash and cover them.

- Follow the SDS: Always keep the Safety Data Sheet handy for each chemical. The SDS has cleanup and disposal instructions. In fact, EPA guidance says to “follow cleanup instructions on the package or… Safety Data Sheet”. In an emergency spill, the SDS will tell you what absorbents to use.

- Do Not Mix: Never dump different chemicals together. EPA warns “Never mix excess products when disposing of them, unless the manufacturer specifically recommends it”. Mixing can cause dangerous reactions or make waste non-recyclable.

- Legal Disposal: Hazardous construction wastes usually must go to a permitted facility. Check local regulations – many cities and states require special handling for things like asbestos, lead paint chips, or chemical sludge. If you’re not sure, consult your local solid waste agency or hire a licensed hazmat handler. Always keep any labels intact (as EPA notes, labels contain key safety info) so disposal workers know exactly what they’re dealing with.

Handling these materials properly is non-negotiable. It protects worker safety, keeps you compliant with laws, and avoids soil/water contamination.

5. Train and Engage Your Crew

None of these plans work if your team doesn’t follow them. Make sure every person on site—from project managers to laborers—understands the waste management routine:

- Kickoff Training: At the project start, hold a brief meeting about waste sorting. Show photos or real examples of what goes in each bin. Explain why it matters (e.g. saving money, protecting environment).

- Use Signage: Post clear signs at each waste station listing allowed materials. Even a simple laminated chart on a wall or bin works wonders. If possible, use pictures (e.g. a picture of bricks under “Concrete”) so language isn’t a barrier.

- Toolbox Talks: Every few weeks, do a quick review on waste practices during a routine safety talk. Praise the crew for successes (like a week with no contaminated bin) and correct any recurring mistakes.

- Incentives: Consider small rewards or recognition. Some sites have friendly contests: “which crew can fill their recycling bin first?” or a shared lunch if the site hits a recycling goal. Positive feedback makes people care more.

An informed and motivated crew is your best asset. When everyone pitches in, sorting becomes second nature. This not only hits waste goals but also keeps the site safer and more organized.

Conclusion

Following these construction waste management best practices will make your job site run smoother and greener. A little planning and daily care on site go a long way: you’ll see fewer dumpster surprises, lower haul bills, and perhaps even revenue from recyclables. Most importantly, you’ll have a safer, cleaner workspace.

At Refuse Fab, we know a thing or two about construction sites. Our custom roll-off containers and bins are built tough for exactly this kind of use. Whether you need a heavy-duty dumpster to handle concrete and scrap metal or a set of labeled recycle bins, our team can help design a solution. Get in touch for a free quote—our experts will work with you to choose the right containers for your project and waste plan.