A fabrication company is a workshop that turns raw materials into custom parts or structures. Typically, they take metal (sometimes plastic or wood) in flat sheets or bars and cut, bend, weld, and assemble it into a specific shape or design. In other words, if you have a metal sketch or blueprint, a fabrication shop can make it real. They often build components that other businesses use – not finished consumer products – such as machine parts, frames, or specialized containers. Think of them as expert builders who work at the part level: for example, a fabricator might cut and weld steel beams for a building, or create the metal tank for a factory machine. In fact, one company notes that metal fabrication is “assembling metal in various shapes and sizes to create a finished product”.

Key Processes and Techniques

Fabrication shops use specialized equipment and skilled labor to shape materials. Common steps include cutting the raw stock to size (using tools like laser cutters, plasma torches, saws or CNC machines), then bending or forming the pieces (often on press brakes or rollers), and finally joining everything by welding or bolting. After assembly, fabricators usually finish the part by cleaning welds, sanding surfaces, or applying paint or powder coating to protect it. These processes require precision – many shops now use CAD designs and CNC automation to ensure each cut and weld is exact. For example, one guide breaks metal fabrication into four main stages: cutting the metal, bending it, assembling the pieces (often with tack welds), and finally polishing or cleaning up the welds for a finished part.

- Cutting: Slicing raw sheet or plate into the needed shapes (e.g. with lasers, plasma, or even just large shears).

- Bending/Forming: Shaping those cut pieces with press brakes or rollers into angles or curves.

- Joining/Welding: Fusing or fastening parts together – for instance, using MIG, TIG, or robotic welding to create a single piece.

- Finishing: Grinding and polishing welds, removing any rough edges, and applying protective coatings or paint.

Each step uses different machinery and expertise. A fabrication shop might employ welders, machinists, and designers who specialize in making complex assemblies. Because of this, fabrication companies can deliver parts that fit together perfectly later on – whether those parts are beams for a building, brackets for a machine, or boxes for heavy equipment.

Products and Applications

Fabrication companies build a huge variety of products, tailored to their clients’ needs. This often includes structural steel (like I‑beams, channels, and columns for construction), custom machinery parts, large industrial tanks or silos, and even metal artwork or signage. One source points out that fabricators make everything from automobile parts, fences, and gates to dimensional metal letters and large structural assemblies. In practical terms, if you see it at an industrial site, there’s a good chance it was fabricated.

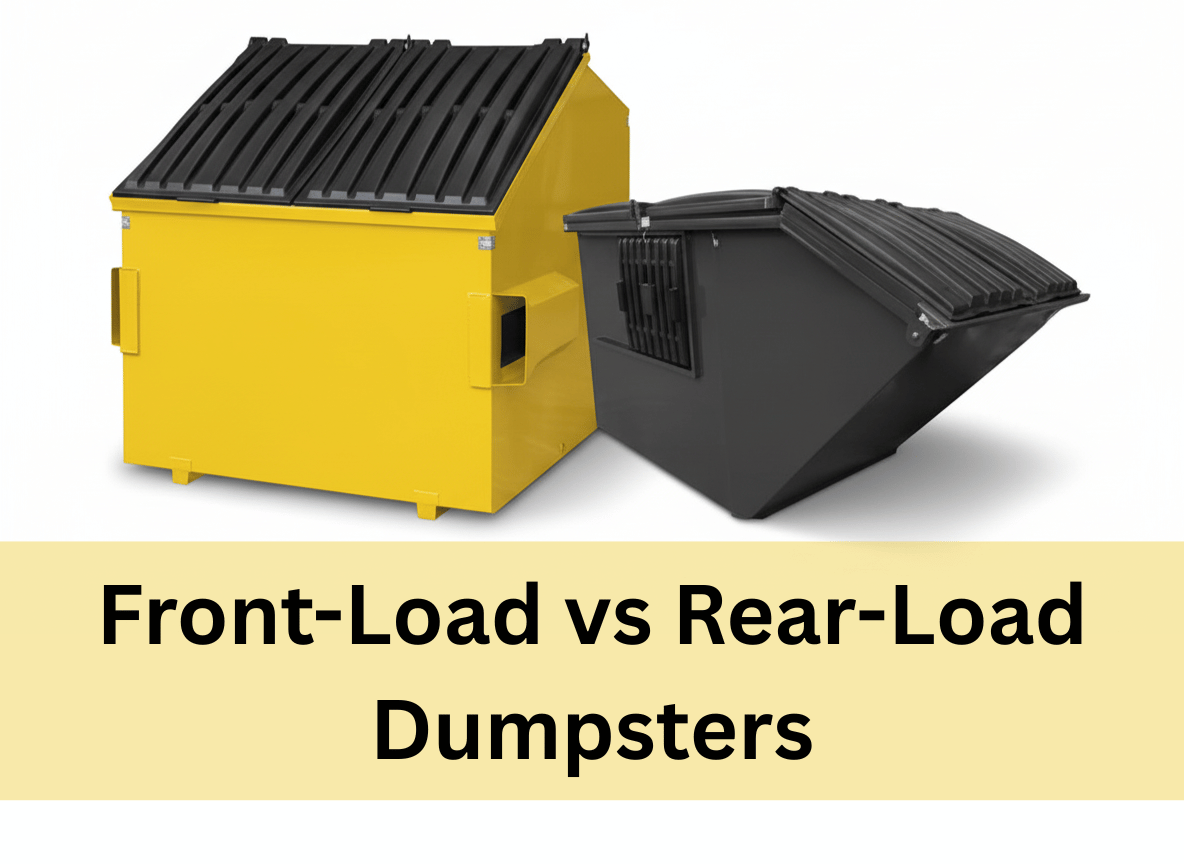

For example, fabricators create the roll-off dumpsters and waste bins you see on construction sites. These heavy-duty containers are made to specific dimensions and tolerances so they stack and hook onto trucks safely. (In fact, Refuse Fab itself “started as a custom fabrication company” making just those kinds of roll-off waste bins.) Other industries rely on fabricated components too: aerospace companies use custom brackets and frames, auto shops need chassis and engine parts, and energy plants require specialized vessels and piping. Altogether, the metal fabrication industry is considered a “linchpin” of the economy, supplying parts to automotive, aerospace, construction, healthcare and many other sectors.

Fabrication vs. Manufacturing

It’s easy to mix up fabrication and manufacturing, but they’re not exactly the same. Manufacturing usually means making a complete product from raw materials (for example, building a finished appliance or phone), while fabrication refers specifically to making the parts or sub-assemblies used in those products. A fabricator might take steel plate and produce a welded frame or housing, but not necessarily build the entire machine or item that uses that frame. In practice, fabrication shops often work as partners to manufacturers: they provide the custom parts that manufacturers then assemble into final goods. As one expert summarizes, manufacturing “involves creating a complete product ready for a consumer,” whereas fabrication focuses on “the creation of component parts that can then be assembled to make a final item”.

Expertise and Industry Role

Fabrication companies are staffed by skilled craftsmen and engineers. You’ll find experienced welders, metalworkers, CAD designers, and inspectors all working together. They use math and material knowledge to ensure every bend angle and weld seam is right – even things like accounting for how metal springs back when bent or how heat affects strength. Modern fabrication shops increasingly use computer-controlled machines for consistency, but the human touch is still important for complex or one-off projects.

Why does this matter? Fabricated parts are the backbone of countless projects. A bridge or skyscraper wouldn’t stand without fabricated steel beams; cars and planes need thousands of custom metal brackets and panels; even everyday items like appliances contain brackets and frames that were first fabricated. Because of this, the fabrication industry has a huge impact: it not only drives construction and manufacturing projects, but also creates tech and jobs. Leading fabricators continuously innovate (using new materials, robotic welding, eco-friendly practices, etc.) to stay efficient and meet tougher specifications.

In short, a fabrication company enables customization at scale. If you need a part that doesn’t exist off-the-shelf – say, a metal container, a machine frame, or a decorative metal piece – a fabrication shop can make it for you. They do this reliably by following proven processes (cutting, forming, welding, finishing) and by leveraging expert skills and tools. Fabrication companies like Refuse Fab have decades of experience in exactly this kind of work, ensuring each custom build is precise and durable. The next time you see a big steel box or a complex metal frame, remember: it was probably crafted start-to-finish by a fabricator’s hands, turning raw plates into the finished product you see.